Performance results of Environment Dimension

ESG Data Platform – Environment Dimension

Environmental Sustainability Management

Environmental Management Policy

The Company operates in the responsibility of the environment, strictly complies with laws, rules, and relevant standard and indicates the impact management guidelines. The impact can happen due to the operation and probably affect the health and safety of the stakeholders and society. The Company realizes that the effective environmental management can reduce the risk of legal issues and the Company’s reputation, moreover, it will enhance the confidence of the stakeholders and community acceptance. The operation emphasizes the environmental policy and related guideline, for example, climate change management, sustainable water management, solid waste management and promotion of biodiversity. The Company supports the practices to reduce the environmental impact which is resulted from the business activities, and contribute to the achievement of the United Nations Sustainable Development Goals, to enable businesses to grow while caring for the environment and society sustainably.

Environmental Protection Performance

1) Energy Management

The energy management is significant to the engineering consulting company since it reduces the operation cost, support the sustainable projects, support the client’s environmentally friendly project development, such as green building and renewable energy (solar rooftop) as well as energy saving technology (smart chiller). However, without the appropriate control, it will lead to the uneconomical use of energy and affect the cost. The non-compliance with energy laws can affect the client confidence and the Company’s image. On the contrary, the effective energy management enables the cost reduction, and increase the competition ability and business expansion with the smart energy service. The Company can also comply with the energy and environmental standard and efficiently support the sustainable development of the engineering industry.

Operational approaches

The Energy Management Implementation Working Team is appointed to implement and cooperate with the Company’s energy management for the best continuation and efficiency. The tasks of the Energy Management Implementation Working Team include operating the energy management to be in consistency with the policy of energy conservation and energy management, and cooperating with the relevant agencies to follow the policy. Moreover, the Energy Management Implementation Working Team will organize the training or the activities relating to the energy conservation for the awareness of all levels of employees, and supervise the energy management to be in consistent with the policy. The Energy Management Implementation Working Team will report the implementation results of the energy conservation and management to the CEO, propose the indication or review of energy conservation and management policy for the CEO’s consideration, and lastly, support the administrative unit to follow the energy law.

The company indicates the energy management guideline for both the internal operation and project operation to respond the targeted policy and goals and support the maximum effective energy use and energy reduction.

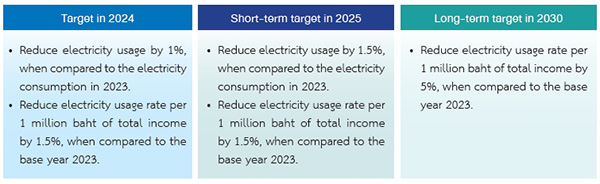

The Company targets the electricity reduction as follows:

Operational approaches

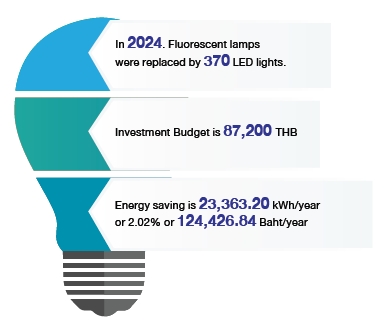

Energy reduction in the work includes the campaign to turn off the light during the lunch break and replace of the energy saving appliances in the whole office building, for example, the energy saving light bulbs (LED) and the study of gas reduction, for example, procurement of electric vehicles (EV) to replace the existing car.

Energy Efficiency Improvement the Company has studied and developed technology for enhancing energy efficiency, especially the building’s cooling system which accounts for a considerable portion of the annual electricity bill. In 2021, the Company installed the smart chiller system at TEAM Building to help reduce electricity consumption.

Energy conservation in the office The energy management implementation working team publicizes the energy saving tips for employees via the internal communication channels, such as intranet, corporate Facebook, information board in the elevator, etc. The energy saving tips involve the campaign to turn the lights off during lunch breaks or when not in use or turn on the air conditioner at a suitable temperature of 25-26 degrees.

Production/use of renewable energy the company invested 2.5 million Baht in the installation of a 90.09 kWp solar power generation system on TEAM Building’s rooftop to covert solar energy, which is clean energy, into electricity for indoor use. This helps to reduce the amount of electricity purchased from the Metropolitan Electricity Authority (MEA) and the power generation system causes no environmental pollution. It is also a measure to reduce the Company’s carbon footprint in terms of global warming.

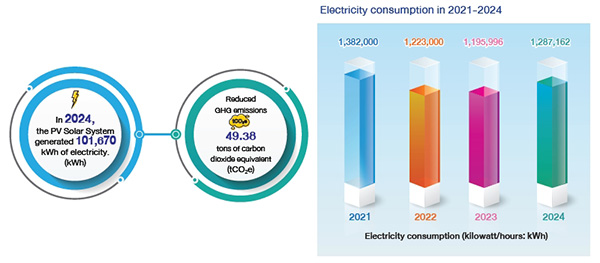

Summary of energy use In 2024, the total of electricity use, including the renewable energy from the solar rooftop is 1,388,832 kilowatt/hours (kWh)

In 2024, the Company’s electricity consumption from the installation of the solar power generation system can be calculated as the greenhouse gas emission reductions in scope 2 or indirect greenhouse gas emissions from electricity use, as follows:

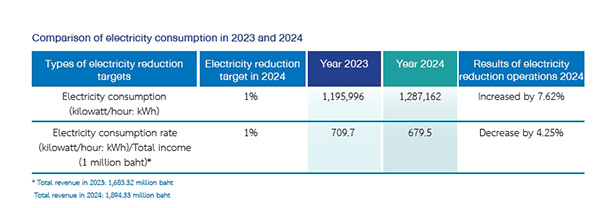

In 2024, the Company’s electricity consumption increased by 7.62% from 2023, due to the increase in the Company’s workload, which is 12.40% increase in revenue growth. The electricity consumption increased by 7.62%, whereas the electricity consumption intensity per income (kWh/million baht) decreased from 709.7 in 2023 to 679.5 in 2024. This shows that even though electricity consumption has increased, the Company has been able to improve its energy efficiency in proportion to the increase in revenue.

2) Water Resource Management

The Company, the consultant company in relating with engineering and water management, emphasizes the efficient water use which can not only reduce the operating costs but also promote sustainable project development, e.g., water management project, waste water management system design and implementation of water-saving technologies. These project developments can increase the efficiency of water resource use, reduce the impact on the environment, promote business expansion and comply with energy and environmental regulations. Neglection in proper water management can leave companies with long-term impacts on their image and stakeholder trust.

Operational approaches

The Company’s Corporate Governance and Sustainability Team, consisting of many business units, focus on supporting all units to manage water resources effectively. The Team indicates the guidelines for reducing water usage, reducing water loss, recycling water used in the organization, installing the water saving devices, providing the management of all wastewater treatment systems resulting from activities within the TEAM building, allowing the relevant agencies to inspect the water leaks and reduce the water loss, as well as organizing the campaign for employees to use water resources wisely and creating awareness of water conservation.

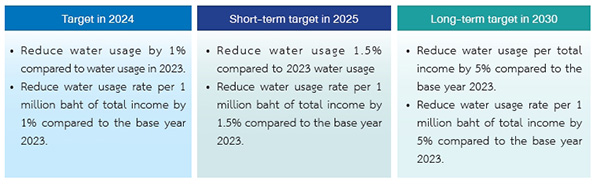

The Company has set the following targets for reducing water usage as follows:

Performance Results

Reducing water usage The Company asks the water users to turn off the water every time when the equipment is not in use, for example, turn off the water when washing hands or brushing teeth, and do not leave the water running while washing dishes. In the construction project, the water circulation system will be used to reduce the fresh water use. The water use activities include collection and treatment of used water from equipment washing and concrete mixing for reuse and selecting water saving devices, such as low pressure nozzles and sensor faucets, in order to reduce unnecessary waste.

Reducing water loss The Company places importance on using water efficiently by improving water use systems in offices and projects, for example, installation of automatic stop faucets, and inspection and repair of water system leaks.

Water reuse/ water recycling the Company encourages the water recycling, such as, using the water from the sink to water plants and employees are suggested to recycle water from washing vegetable and fruits to water the plants, etc.

In addition, the Company invested in the innovation, for example, water recycling in the area of Suan Luang – Sam Yan, which belongs to Chulalongkorn University in 2019. The project has the production capacity of not less than 240 cu.m./day. The wastewater from the consumption of CU-Terrace and CU I-HOUSE buildings will be treated and distributed back to Chulalongkorn University for watering the plants in Chulalongkorn University Centenary Park and neighboring area. The project duration is 11 years, from 2020 – 2031.

Wastewater Management the Company has established guidelines for managing all wastewater treatment systems resulting from various activities within the TEAM Building, using a fixed film aeration system with a size of 100 cubic meters/day. The wastewater quality will meets the standards for controlling wastewater discharge from buildings, according to the announcement of the Ministry of Natural Resources and Environment, before discharging into the public water drainage system.

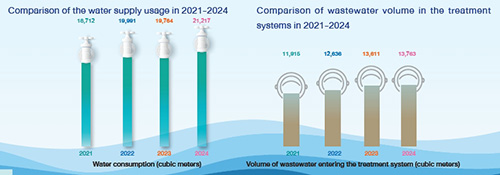

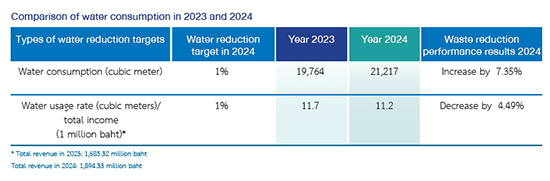

Summary of the Company’s total water usage In 2024, the different types of water usage of the Company is as follows:

o Water supply is the total of 21,217 cubic meters.

o The total wastewater discharged into the treatment system is the total of 13,763 cubic meters.

In 2024, the Company’s water consumption increased by 7.35% from 2023, due to the increase in the Company’s workload, which is 12.40% increase in revenue growth from 1,685.32 million baht in 2023 to 1,894.33 million baht in 2024. Although water consumption volume increased, water consumption intensity per revenue (cubic meters/ million baht) decreased from 11.7 in 2023 to 11.2 in 2024. This shows that the Company is able to improve water usage efficiency in comparison to revenue growth.

3) Waste and Solid Waste Management

The Company focuses on efficient waste and solid waste management to reduce operating costs and supports sustainability practices. The management includes reducing the amount of paper used in preparing reports, recycling document, and reducing the waste generated from internal processes within the organization. The appropriate waste management enables efficient use of resources, reduces the environmental impact and enhances the credibility in environmentally friendly business operations.

Operational approaches

The Company’s Corporate Governance and Sustainability Team is responsible for establishing effective waste and waste management guidelines, emphasizing the reduction of the waste and the landfill, and promoting the recycling, as well as establishing waste separation measures from the beginning and recycling of reusable waste. The Administrative and General Services Unit is responsible for operations in accordance with the specified guidelines, for example, providing waste separation bins according to type, responsible for the waste recycling process and checking the amount of waste generated in the office. The Administrative and General Services Unit will cooperate with the Corporate Communications Department to encourage employee of all levels to reduce the waste and use the resource wisely. This is the Company’s waste management that is in line with the environmental and sustainability standards.

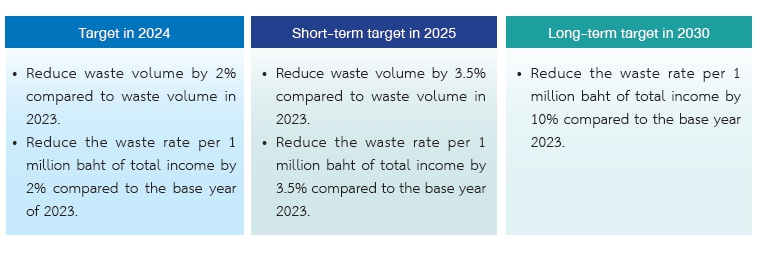

The Company has set a goal to reduce the waste in the organization as follows:

Performance Results

Reduction of the waste and waste generation

The Company indicated the policy for the office to store the document in the digital format and sent by email. This is the policy of the paperless work. The document in the work include meeting agenda of various committees and employee valuation form, etc. The document management system is adopted all projects related to construction management and supervision which results in the reduction of hard copies such as circular letters, accounting, financial, and procurement documents. The 3R (Reduce, Reuse, and Recycle) concept is employed in the project site. This concept will reduce the unnecessary material, and sort the material that can be reused, for example, wood, scaffold, and pieces of metal. The waste material can be sent to the recycle factory to reduce the waste.

Reduction of the landfilling, such as separating, recycle, and reusing waste

The Company is committed to reducing and making use of solid waste in line with the 3Rs (Reduce, Reuse and Recycle) approach, especially with respect to wastepaper generated by report preparation. An active measure is to ensure that both sides of paper are used for printing. When such paper is no longer needed, it is sold for recycling.

Staff members are also encouraged to sort the plastic bottle for recycling and use quality eco-friendly office equipment.

Educating and promoting employee participation In 2024, the Company implemented the project of properly sorting plastic and organic waste (food scraps). The separate trash bins for plastic bottle and food scraps are provided. The sorted plastic bottles were donated to the gas station for recycle supporting, and reduction of landfill.

The Company has campaigned for employees to reduce waste generation to be less than 0.3 kilograms/person/day. In 2024, employee generates the waste at a rate of 0.34 kilograms/person/day.

Summary of the amount of various types of waste in 2024

In 2024, the Company’s waste volume decreased by 70.33% from 2023. The intensity of waste volume per income (tons/million baht) decreased from 0.077 in 2023 to 0.020 in 2024, representing a decrease rate of 73.61%. Nevertheless, in 2023, the Company calculated by employing the average waste generation rate, while in 2024, the Company employed the weighting method. However, in 2024, the Company can improve its waste management efficiency in spite of the continuous business growth. The Company’s hazardous waste is small and it is considered insignificant.

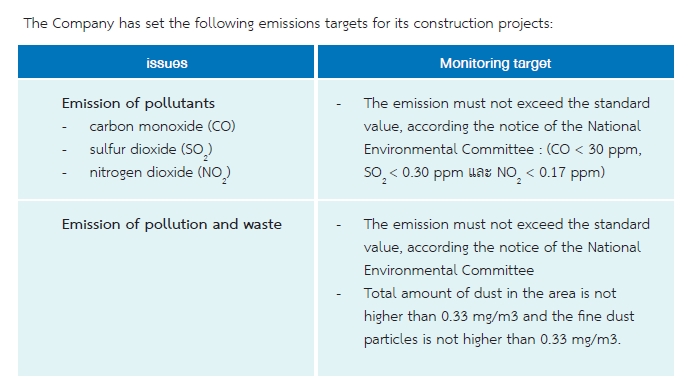

4) Air pollution management

The Company is the construction supervisor and contractor in the project sites. The construction supervision and management unit strictly complies by the policies of environmental impact prevention and reduction as indicated by the relevant regulations. The indicated practices will control the impacts from the air pollution and the waste to the least possible extent. The impacts from the construction include the total suspended particulates (TSP), carbon monoxide (CO), sulfur dioxide (SO2), nitrogen dioxide (NO2), noise pollution, wastewater and solid waste. The construction area and the access road are sprayed with water. The truck tires are washed before leaving the construction site. The machine and equipment are carefully inspected to ensure the normal condition and prevent the noise. The construction hours do not affect the nearby communities. The wastewater in the construction area is treated before discharging. The waste is managed by the 3R system (Reduce, Re-use and Recycle) before disposed by the authorized agencies outside of the project area.

Monitoring of air quality and noise from construction activities are conducted by regularly measuring the concentration of TSP, CO, SO2, NO2, maximum noise level, and 24 hour average noise level in the construction area, community area and nearby sensitive area. The monitoring will follow the efficiency of measures implementation to prevent and reduce environmental impacts, and monitor the impact of construction activities to the workers in the construction area, the local people in the community and nearby sensitive area.

The aforementioned activities build the trust with its customers, practice as indicated by the environmental regulations and promote the environmentally friendly construction guidelines. However, the lack of appropriate control measure will affect the air quality and noise level and result in the community complaint and risk of non-compliance with environmental laws. Therefore, the regular monitoring of air quality and noise level is crucial in the effective management of impact from the construction activities.

Operation approaches

มาตรการเพื่อลดการปล่อยมลพิษทางอากาศ ของบริษัท มีดังนี้

The construction supervision and management unit can indicate the measures of air pollution control and emission for the contractor as follows:

- The machine in the project should have the Euro 4 standard or higher, to reduce the emission of CO2 and Nox.

- Spray the dust suppressant or water every 2 hours to reduce the dust from the soil digging and transportation.

- The truck must be covered with tarpaulin to reduce the dispersion of dust during the transportation.

- Prepare the shortest route and avoid the route with traffic congestion to reduce the CO₂ emission.

- Select the construction material that is produced with the low carbon emission process, for example, concrete that is made from the recycled material or mixed concrete.

The control and monitoring of the air pollution emission reduction results is the crucial tasks for the construction supervision consultant. The measure is conducted every 3 months in the construction area. The monitoring guidelines are as follows:

- Monthly monitor the used fuel amount in the machine and vehicles and compare with the indicated target.

- Regularly monitor the air quality in the construction area and surrounding area and report to the related agencies.

- Report the emission value of CO2 and dust particles in the construction area every quarter in the sustainable report of the project.

- Check the machine and vehicles and maintain the scheduled maintenance to reduce the pollution emission.

Results of pollution of pollution and waste control and monitoring operations in the construction projects

All of the results of pollution emissions control from the construction does not exceed the specified standard. This certified the responsibility for compliance with environmental measures for the protection of environment and surrounding community’s health.

In 2024, the Company implemented the Environmental Benefits Study Project for the Government’s Use of Electric Vehicles, for Department of Climate Change and Environment, a consulting project that contributed to reducing air pollution emissions. The objectives of the project involve the study of the environmental impact and reduction of the greenhouse gas emission, with the use of electric vehicle (EV) to replace the internal combustion vehicle in the government agencies. The project develops the calculation of greenhouse gas reduction and survey vehicle usage data of government agencies, study the economic costs and benefits of electric vehicle and the internal combustion vehicle, study the environmental benefits and develop a low-carbon business model to drive EV policies for the whole country, and suggest the solutions to the problem of switching to EVs nationwide. This project supports the reduction of greenhouse gases, reduces the environmental impact of using gasoline-powered vehicles, and reduces the generation of PM 2.5 dust and various pollutants, for example carbon dioxide (CO₂), nitrogen oxides (Nox), carbon monoxide (CO) and noise pollution, etc.

5) Management to reduce the greenhouse gas problems

Management to reduce greenhouse gas emissions is an important issue that the Company places great importance on since it is a part of environmental responsibility and sustainable business operations. The Company, as the engineering and environmental consultant, expands the scope of service to the corporate carbon footprint assessment and Validation and Verification Body (VVB). This service will assist the client to systematically manage their greenhouse gas emissions and comply with international environmental standards. The opportunity of this operation allows the Company to respond to the business sector that emphasizes the carbon reduction, support sustainability requirements and add the value to the Company’s services. However, the inappropriate management may result in the Company being unable to comply with government requirements and international standards on greenhouse gas verification and affect the customer credibility and trust. Consequently, effective implementation of this work and development of capacity to provide carbon footprint and GHG verification services are therefore essential for the Company in relation to the ability to compete and grow in the long term.

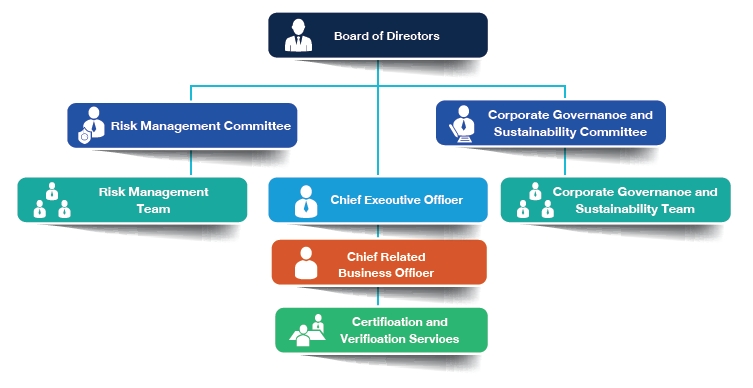

Operation approaches

The Company places importance on reducing greenhouse gas emissions, both in its operations and in its work processes. The Company has defined the roles and responsibilities of the Board of Directors and Executives related to climate change as follows:

The Risk Management Committee The tasks include supervision and management of the risk in terms of ESG, especially the risk in the climate change that is able to affect the Company business operation. The Risk Management Committee is assigned by the Company’s Board of Directors to indicate the ESG Risk Management Policy and Framework to be in line with the corporate strategy and supervise the Company’s adaptation and reduction of the effect of the relevant risk.

Corporate Governance and Sustainability Committee The Committee has a key role in determining sustainability policies and strategies to ensure that the Company operates in accordance with the principles of good governance and sustainability, particularly, managing the impacts of climate change and other ESG factors. The Committee establishes a vision and operational guidelines for ESG, including monitoring compliance with the established policies.

Corporate Governance and Sustainability Team It is the operational unit that consists of the top management from all of the business units in the Company. The group is responsible for operating in accordance with the ESG policies and strategies assigned by the Corporate Governance and Sustainability Committee and the Risk Management Committee. The tasks include identification of the risk factors and opportunities resulting from climate change, setting of the targets to reduce greenhouse gas emissions, monitoring and measuring ESG performance to ensure that defined measures are achieving their goals, and continuous reporting of operating results to the Board of Directors.

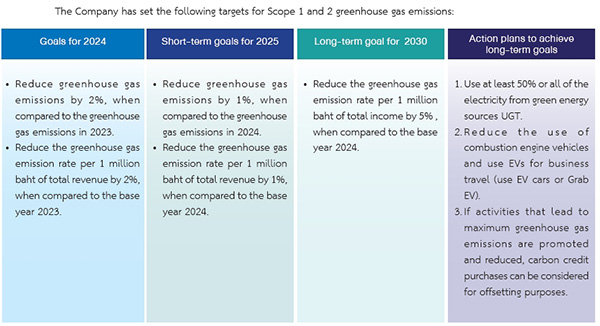

The Company also aims to become carbon neutral by 2050 and achieve net zero greenhouse gas emissions by 2065, to be in line with Thailand’s goals.

Performance results

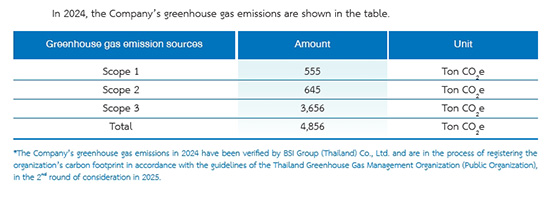

In 2024, the Company has collected data and calculated the amount of greenhouse gas emissions of the organization adopting the carbon footprint assessment guidelines of the Thailand Greenhouse Gas Management Organization (Public Organization), with details as follows:

- Direct greenhouse gas emissions (Scope 1) are caused by the Company’s combustion of various fuels such as diesel, gasoline, refrigerant leaks, and methane (CH4) leaks from the septic tank systems.

- Indirect greenhouse gas emissions (Scope 2) are caused by the Company’s use of electricity, as detailed in the section on “Energy Management”.

• Other indirect greenhouse gas emissions (Scope 3) are caused by purchasing equipment, tools and supplies, paper use, water supply consumption, air travel, and the amount of waste in the organization.

The Company has established guidelines to reduce greenhouse gas emissions by focusing on reducing electricity consumption as outlined in the “Energy Management” section, as well as reducing the use of resources and consumables such as paper, plastic bottles, and bags. Materials are reused, and a Paperless policy has been adopted in various work processes, including the use of digital documents in board meetings and the reduction of internal circulation documents, such as accounting and finance documents, and procurement documents.

The Company has changed its base year from 2023 to 2024, covering 1 January to 31 December 2024, to serve as a reference year for calculating greenhouse gas emissions and preparing the Company’s greenhouse gas inventory for comparison with other years. In 2024, the Company has collected additional data to cover all activities in order to reflect the activities that have occurred and calculate the amount of greenhouse gases to be in line with the facts as much as possible.

The Company’s total corporate greenhouse gas emissions in 2024 was 4,856 tCO₂e, which can be separated into activities with the highest greenhouse gas emissions in each area and the guidelines for reducing greenhouse gas emissions as follows:

Scope 1: The combustion of gas combustion in the vehicles of the organization accounts for 99% of the greenhouse gas emissions in Scope 1. The organization is currently studying the operation to reduce the gas use, such as purchasing EVs to replace the existing cars.

Scope 2: The electricity consumption in the office accounts for 99% of greenhouse gas emissions in Scope 2. The Company has organized the activities and campaigns for employees to participate in saving electricity, such as turning off lights when not in use or during the lunch break, setting the air conditioner at an appropriate temperature of 25 – 26 degrees Celsius, and turning off the air conditioner during the lunch break of 1 hour.

Scope 3: Purchase of equipment, tools and appliances accounts for 66% of Scope 3 greenhouse gas emissions. The Company campaigns for employees to economically use the water supply, adopt the concept of the paperless work and sort the waste for recycling.

6) Quality of Construction Materials

Environmentally friendly construction material management is important for the Company as it minimizes environmental impacts and strengthens the Company’s image as a sustainability-focused engineering consultant. Promotion of green building design according to LEED and TREES standards, support for the use of energy-efficient materials and greenhouse gas emission reduction, including selection of materials that have undergone Life Cycle Assessment (LCA), have provided opportunities for the Company to expand its business in environmentally conscious markets. However, selection of unsuitable construction materials or non-compliance with construction material regulations may have a negative impact on the Company’s image and lead to a loss of customer trust. Therefore, controlling the use of construction materials according to the established standards is crucial for reducing risks and achieving sustainable growth in the future.

Operational approaches

As a design and construction supervision consultancy, the Company plays an important role in setting guidelines and measures for construction waste reduction in order to enhance the efficiency of resource use, minimize environmental impacts, and promote environmentally friendly operations. The Company has established the following guidelines.

• Selection of Construction Materials

The Company defines measures for efficient selection and use of construction materials, focusing on reusable or recyclable materials, such as waste glass in concrete mixes and recycled steel bar, including design of buildings and structures, taking into account the use of environmentally friendly materials and mitigation of long-term environmental impacts.

• Construction Waste Reduction

The Company is committed to maximizing material efficiency from the design phase in order to minimize construction waste. A Construction Waste Management Plan (CWMP) is required to be prepared as part of the construction plan and these guidelines must be strictly adhered to.

• Use of Construction Waste

The Company supports the processing and reuse of construction waste, such as grinding old concrete to be used as fill material, and exchanging excess construction materials between projects for use in other projects. Guidelines are put in place for the storage and reuse of used materials, such as formwork which can be reused multiple times, so as to increase resource efficiency and minimize environmental impacts.

As a construction supervision consultant, in 2024, the Company and construction contractors jointly set waste management goals, with waste reduction target of not less than 20% of the total waste generated in construction projects. Waste reduction measures are implemented from the design stage, planning of material use, transportation, construction, and management of waste generated in projects.

Performance results

- Employee Training In 2024, the Company conducted training for employees on effective construction waste management. The training focused on providing knowledge about waste management standards according to ISO 14001 and LEED standards, including waste separation, efficient resource utilization, and guidelines on waste recycling. Furthermore, training was held on waste reduction methods from project design to on-site construction to enable employees to effectively implement these practices.

- Contractor Training The Company puts emphasis on educating contractors about construction waste management. Training was conducted in 2024, covering waste management standards, requiring contractors to prepare a waste management plan as part of the construction plans, and continuously monitoring and evaluating waste reduction performance.

- In 2024, with the waste reduction target of not less than 20% of the total waste generated in construction projects, the inspection and evaluation of waste management within the project showed that waste could be reduced by 25% compared to the total waste from construction projects. This was achieved through the following actions:

- Waste sorting at source: Designated disposal points are arranged for different types of waste, such as concrete, scrap metal, plastics, and wood.

- Use of recycled materials: Minimizing waste from cutting steel bars, and reusable concrete where possible.

- Waste reduction during construction: Use BIM (Building Information Modeling) technology to calculate the actual work quantity required so as to reduce construction waste and reduce losses from incorrect construction placement.

- Reuse of materials: For example, plywood formwork can be reused multiple times.

7) Biodiversity Management

Biodiversity management is a key factor that the Company prioritizes as an engineering and environmental consultant. Emphasis is put on project design that helps protect and restore ecosystems, along with risk assessment and planning for prevention of probable environmental and social impacts through pollution control and waste management. In addition, the Company implements measures for conserving refuge areas and biological resources in accordance with EIA principles, with continuous monitoring and reporting. The Company has carried out EIA projects for a large number of clients. Opportunities from good management enable the Company to add value to projects, respond to environmental policies, and build confidence among stakeholders. However, without proper management, there could be impacts on ecosystems and communities, including risk of non-compliance with environmental laws, which can affect reputation and business opportunities in the long term. Consequently, systematic implementation of biodiversity measures is a key approach that enables the Company to grow sustainably and reduce environmental impact.

Operational approaches

The Company’s steps or process for biodiversity study in the environmental impact study and report preparation are as follows:

- Define the scope and methodology.

- Survey, count and assess the abundance, diversity, and legal protection.

- Assess biodiversity risks and impacts.

- Determine measures for impact prevention, correction and mitigation.

- Determine monitoring measures to observe potential impacts to ensure the sustainability of ecological system and biodiversity in project development.

- Promote public participation and receive opinions about project development approaches.

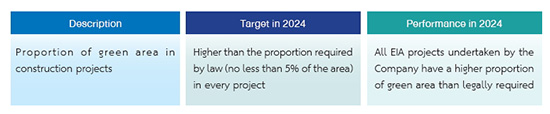

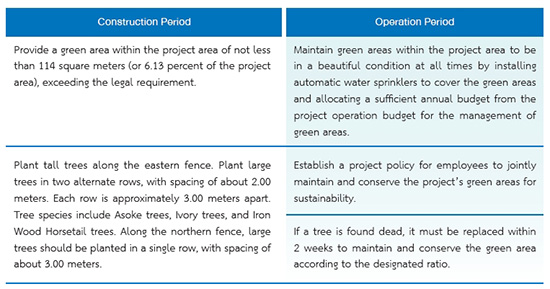

The Company sets biodiversity management targets as follows:

Performance results

The Company’s engineering and environmental consulting business plays a part in the promotion and conservation of environmental quality. In 2024, the Company, together with Kansai Energy Solutions (Thailand) Co., Ltd. preserved and protected biodiversity affected by construction process. An Environmental Impact Assessment (EIA) was carried out to minimize any probable negative environmental impacts in the project. The Company conducted survey and assessment of biodiversity impacts from the construction of Kansai Power Plant Project. It also participated in determining impact prevention and correction measures as well as environmental impact monitoring measures during the construction and operation phases. This is to maintain and conserve environmental quality, ecosystem or biodiversity, and social aspects in order to ensure sustainability in the project development and create understanding among communities through public participation activities according to the public participation and consultation process, public opinion survey regarding project development, and survey of ecosystem or biodiversity, environmental quality and health, including participation in monitoring and surveillance of environmental quality and health impacts in the biodiversity aspect that may occur during the project construction phase. Additionally, the Company participated in determining measures for preventing and mitigating impacts on terrestrial biological resources as follows:

The Environmental Impact Assessment (EIA) Report for Kansai Power Plant Construction Project of Kansai Energy Solutions (Thailand) Co., Ltd. can be downloaded at https://eia.onep.go.th/

Summary of Environmental Performance

In its 2024 operations, the Company strictly adhered to the environmental policies and laws, resulting in no environmental dispute or violation of relevant laws or regulations.